Site Menu

Lynchburg Glass

Site Contents

CD Styles

Insulator Features

Mysteries

Anomalies

Production Data

Historical Archive

Gayner

Birmingham

|

Lynchburg Glass Corporation This is a Lynchburg Glass Corporation advertising brochure giving information about the plant. The brochure lists "One Miller Machine & Mould Works, Model J Telescopic Jar Machine No. 365." We know from board meeting Minutes that purchase of this machine was not approved by the board until January 13, 1925, so it dates after that time. -1- This brochure was a modified version of a "For Sale" advertisement that appeared in the trade journal The Glass Industry in December, 1922, advertising the sale of the original Lynchburg Glass Works plant and equipment. The same photo was used, with the sign on the office building edited to read "Corp." instead of "Works." It is likely that this brochure was created to use in W. H. Loyd's attempts to sell the plant or interest prospective investors in restarting the plant. There are several references in Mr. Loyd's letters to a brochure that gives information about the plant. -2- Original document was scanned by Dennis Bratcher and converted to text. A scan of the original is below.

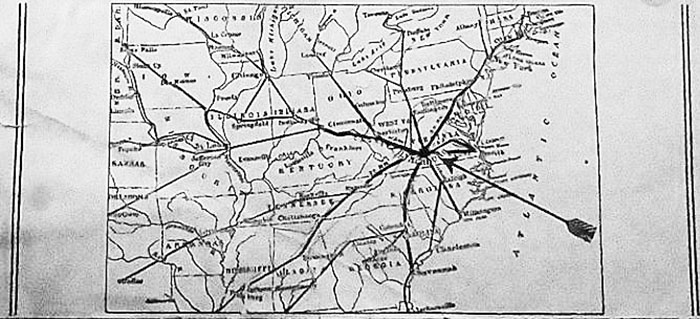

Location Lynchburg, Virginia, on main line of the Chesapeake & Ohio Railroad from Newport News to Cincinnati, Ohio; on main line of Southern Railway from Washington, D.C. to Atlanta, Ga.; on main line of Norfolk & Western Railroad from Norfolk, Va., to Toledo, Ohio. Distance from Lynchburg to the following cities: Norfolk, Va., 204 miles; Washington, D. C., 174 miles; New York City, 400 miles; Philadelphia, Pa., 310 miles; Baltimore, Md., 220 miles; Richmond, Va., 150 miles; Petersburg, Va., 123 miles; Atlanta, Ga., 474 miles; Charlotte, N.C., 200 miles; Greensboro, N.C., 115 miles; Roanoke, Va., 56 miles. Lynchburg is one of the Virginia cities rate-basing points for the entire Southern territory. Real Estate The plant is located at the corner of Anne and Hudson Streets, on a lot containing 5.072 acres. A siding from main line of the Southern Railway runs through the property. Buildings The main building is 198 x 100 feet, two stories high. First story is concrete with concrete floors in back of and between furnaces, as well as in front up to front of lehrs. The Batch House is 55 x 45 feet, two stories high. This building has three bins for storing soda ash, lime and sand, running from ground through second story to roof. Material is unloaded direct from cars on trestle level with top of bins. Automatic batch mixer is located on second floor. Material is assembled and weighed on first floor, and conveyed by machinery to batch mixer, which is located back of furnaces. Power House This building is 50 x 37 feet, frame, with iron siding and roof; contains boilers, compressors and pumps. Producer House This building is 64 x 37 feet, and is built of brick with iron roof. The second floor is reinforced concrete, and on line with bottom of coal dump and top of producers. Box Shop This building is 38 x 30 feet, and contains all machinery for the manufacture of boxes and shipping crates and cases. Ware Sheds This shed is 80 x 48 feet, entirely under roof. It is located so that finished ware is carted by trucks from packing-room to shed a short distance. Oil Storage Oil tank has capacity of twenty-two thousand gallons, and is filled direct from tank cars by gravity. Equipment Two Furnaces with daily capacity of 35 and 45 tons, respectively. Eight rings each. Continuous gas-fired, regenerative. One Beckwith Machinery Co. Automatic Batch Mixer, electric driven. Two 66-inch by 18-feet Horizontal Return Tubular Boilers, complete with feed pump and water heater. One 12 x 14 x 12 steam-driven Duplex Air Compressor. One 14 x 16 x 14 Duplex Air Compressor, steam driven, all complete with storage and regulator tanks. One Oil Pump and Stand Pipe. Four Cox No. 11 Gas Producers, all complete. One Oneill No. 30 Automatic Bottle Blowing Machine. [see The O'Neill Bottle Machine]

Equipment--- (Continued) Five Cox Semi-Automatic Bottle Bowing Machines One Miller Machine & Mould Works, Model J Telescopic Jar Machine No. 365, complete with set each Pint, quart and Half-Gallon Mason Jar Moulds. One Gayner Automatic Insulator Machine with Mould equipment for Glass Insulators standard styles from 9 to 24 ounces. Four Hand Presses for the manufacture of Glass Insulators of various standard styles from 9 to 35 ounces. Two Brookfield Automatic Glass Insulator Presses. Two O'Neill Flows, one used on the Miller Jar Machine, the other on the Gayner Automatic Insulator Machine. These Flows were bought outright and are not subject to a royalty charge. Two Fans with cooling system complete. Five Oil Fired Annealing Lehrs, 65 feet long having tunnels 7 feet wide. Machine shop equipped for the manufacture and repair of moulds. Box shop equipped with cut off and rip saws. Moulds for a general line of Soda Bottles including Coca-Cola. The cooling Fans, Box Shop, Batch Mixer and Machine Shop are operated with motors. One 15 H. P. Generator for making lights. Many other small tools necessary to the operation of a glass plant. Two-story Office Building with necessary furniture including two Iron Safes. Lynchburg is very near the Norfolk & Western and Chesapeake & Ohio coal fields which produce the finest gas coal known. One of the largest plants producing Soda Ash is within 150 miles of Lynchburg. The labor situation in Lynchburg is good. There is an abundance of intelligent labor both colored and white, male and female. Scan of Original

Reverse

Notes 1. Minutes, October 15, 1924; Minutes, November 17, 1924; Minutes, January 13, 1925. 2. [not yet available] |

Copyright © July 21, 2018 , Dennis Bratcher

Last modified: July 21, 2018 10:16 AM